Welcome to MicroBitLogic

About Us

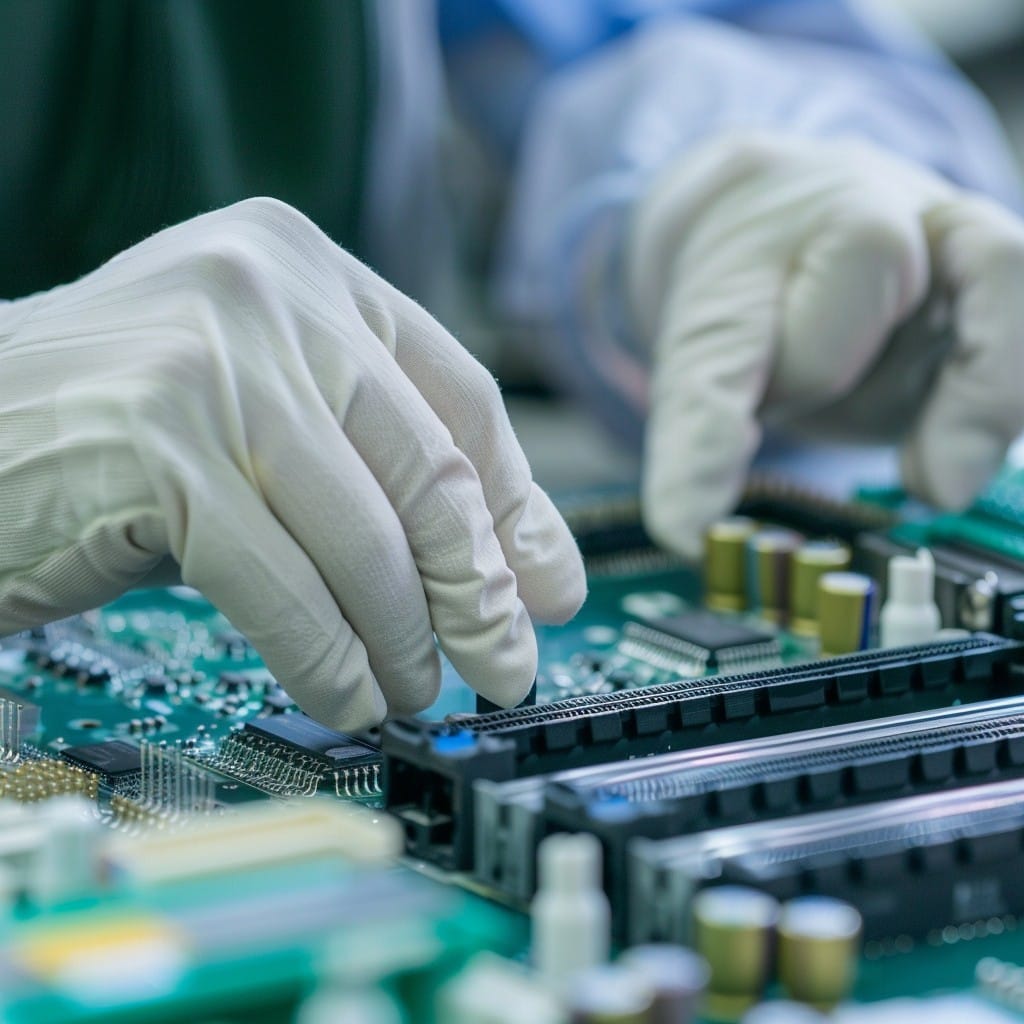

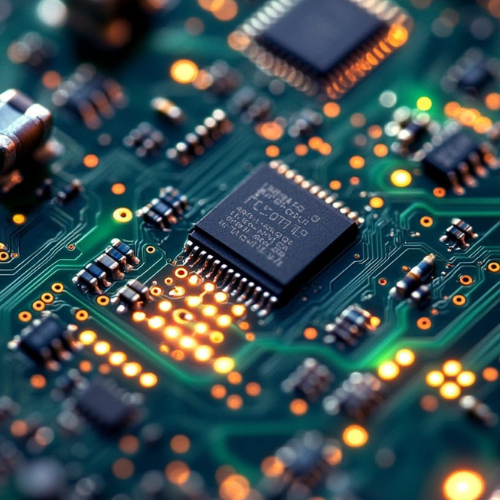

Welcome to MicroBitLogic, your trusted partner for PCB sub-assembly solutions in Singapore. As a new and dynamic startup, we bring fresh perspectives and cutting-edge technology to meet the evolving demands of the electronics industry. At MicroBitLogic, our mission is to provide high-quality PCB sub-assemblies that deliver precision, reliability, and efficiency, tailored to the specific needs of our clients.

Why Choose MicroBitLogic?

Expertise

Our team consists of experienced engineers who are passionate about delivering high-performance sub-assemblies.

Quality Assurance

We adhere to stringent quality control measures to ensure that every product meets international standards

Customer-Centric

We work closely with our clients, providing transparent communication, timely updates, and support throughout the entire production process.

Our Services

Step 1

PCB Sub-Assembly

We specialize in providing comprehensive sub-assembly solutions, from component procurement to full PCB assembly and testing.

step 2

Prototype Development

Whether you’re working on a prototype or full-scale production, we offer flexible services to suit your project needs

step 3

Custom Solutions

MicroBitLogic offers customized PCB sub-assembly services that cater to unique product specifications and industry requirements.

Industries We Serve

- Consumer Electronics

- Automotive

- Industrial Machinery

- Medical Devices

- Telecommunications

Our Commitment

At MicroBitLogic, we are committed to sustainability and innovation. We continually strive to minimize our environmental impact while offering the highest level of service. By partnering with us, you can be assured of receiving top-tier solutions that keep you ahead of the competition.

PCB Sub-Assembly Process

- Design: Create the circuit design and PCB layout.

- Fabrication: Manufacture the bare PCB using the design files.

- Component Sourcing: Obtain and prepare all necessary electronic components.

- Solder Paste Application: Apply solder paste to the PCB pads where components will be placed.

- Component Placement: Place components on the PCB, either automatically or manually.

- Soldering: Use a reflow oven or wave soldering to permanently attach components.

- Inspection: Check for defects and test functionality.

- Final Assembly: Combine the sub-assembly with other parts if needed.

- Packaging: Package the finished sub-assemblies for storage or shipping.

Contact Us

We’re here to assist you with any inquiries or project needs. Feel free to reach out to us using the details below, and we’ll get back to you promptly.

Reach us through

- 30 MANDAI ESTATE #04-07 SINGAPORE (729918)

- info@microbitlogic.com

- sales@microbitlogic.com